Load testing evaluates your battery by applying a controlled current to simulate real-world use, measuring how well it maintains voltage and capacity under demanding conditions. Conductance testing, on the other hand, checks your battery’s internal condition quickly and non-invasively by analyzing its ability to conduct high-frequency signals, without discharging it. Knowing when to use each method helps guarantee safe, reliable performance—keep going to discover more about these testing options.

Key Takeaways

- Load testing simulates real-world usage by applying a direct load to evaluate battery capacity and performance under operational conditions.

- Conductance testing measures internal impedance using high-frequency signals, providing quick, non-invasive health assessments without discharging the battery.

- Load testing offers detailed insights into actual capacity and potential weaknesses but can be more invasive and time-consuming.

- Conductance testing is faster and ideal for routine checks, though less comprehensive, and may not detect internal shorts or internal damage.

- Choosing between them depends on the need for detailed analysis versus quick, routine diagnostics, ensuring optimal battery maintenance.

What Are Load Testing and Conductance Testing?

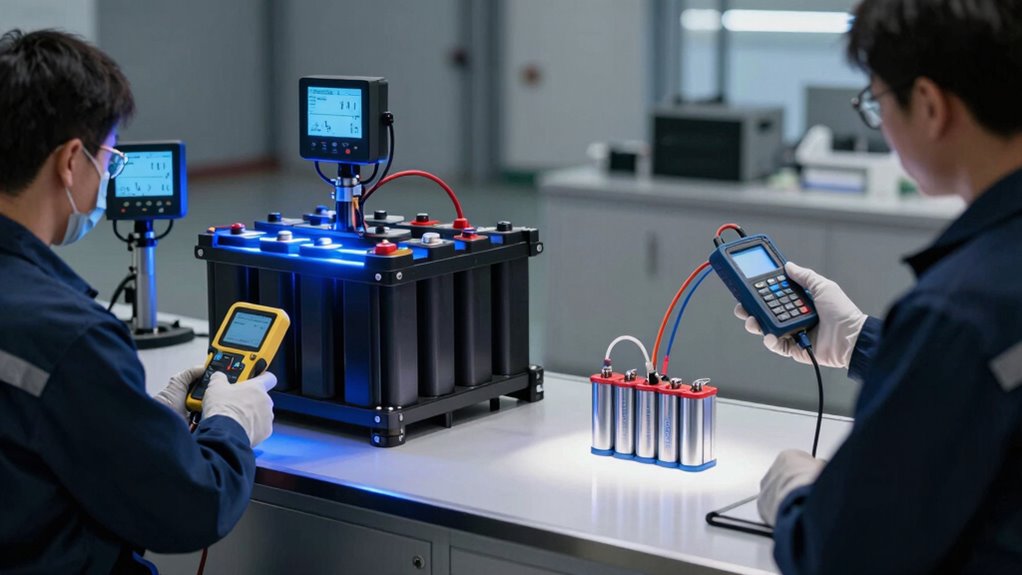

When testing batteries, understanding the difference between load testing and conductance testing is essential. Load testing applies a direct current to the battery, simulating real-world use, and measures how well it maintains voltage under stress. Conductance testing, on the other hand, assesses the battery’s internal condition by measuring its ability to conduct electrical signals, often using specialized instruments. Different testing standards guide these methods, ensuring consistency and safety across various battery chemistries, such as lead-acid or lithium-ion. Understanding which test suits your battery’s chemistry helps you obtain accurate results and avoid unnecessary replacements. Both methods provide valuable insights, but they serve different purposes depending on the battery type and application. Additionally, understanding the testing procedures involved can help ensure reliable results and proper maintenance practices. Mastering these distinctions leads to better maintenance and longer-lasting batteries, especially when considering battery chemistry and its influence on testing accuracy. Being aware of battery performance indicators can further enhance diagnostic precision and proactive care. Recognizing the importance of testing standards ensures that your testing methods adhere to safety and reliability guidelines. Moreover, selecting the appropriate testing method can significantly impact the lifecycle management of batteries, extending their operational lifespan.

How Does Load Testing Evaluate Battery Performance?

Load testing mimics real-world usage to see how your battery performs under actual conditions. You’ll monitor voltage and current levels to identify potential weaknesses or failures. This approach gives you a clear picture of your battery’s true capacity and reliability. Additionally, understanding auditory processing skills can help in diagnosing underlying issues that may affect performance. Incorporating performance testing methods can further optimize your battery maintenance and extend its lifespan. Engaging in accurate diagnostic techniques can also provide deeper insights into battery health and help prevent unexpected failures. Employing smart monitoring technology can enhance the accuracy and efficiency of your testing procedures, especially when combined with natural pool design principles to create a sustainable testing environment.

Real-World Usage Simulation

Real-world usage simulation plays a crucial role in evaluating a battery’s true performance under typical conditions. By mimicking actual operating scenarios, load testing helps you assess how well the battery supports daily demands and maintains its capacity over time. This approach provides insights into its impact on battery lifespan, revealing potential weaknesses that might not be obvious through static tests. It also highlights the importance of proper maintenance routines, which can extend your battery’s longevity and ensure consistent performance. When you simulate real-world loads, you identify how the battery responds during periods of high or fluctuating demand. This helps you make informed decisions about replacements or updates, ultimately maximizing reliability and reducing unexpected failures. Incorporating proper testing methods into your maintenance routine ensures you understand your battery’s true condition and performance capabilities. Additionally, utilizing accurate load testing techniques ensures that results closely reflect actual operating conditions, providing more reliable data for decision-making.

Voltage and Current Monitoring

Voltage and current monitoring are vital components of load testing because they provide real-time data on how a battery performs under stress. As you apply a load, you’ll observe current fluctuations that reveal how well the battery can sustain power. Stable voltage levels during the test indicate good health, while significant drops signal potential issues. Monitoring these parameters helps you identify weaknesses, such as internal resistance or capacity loss. Variations in current draw can also highlight inconsistencies in performance, guiding maintenance or replacement decisions. By paying close attention to voltage stability and current fluctuations, you guarantee an accurate assessment of the battery’s ability to handle real-world demands. This detailed monitoring is indispensable for predicting future reliability and optimizing battery lifespan. Understanding performance metrics like voltage stability and current fluctuations is essential for a comprehensive evaluation, especially since these indicators can reveal underlying battery degradation processes that may not be immediately apparent.

How Does Conductance Testing Check Your Battery Without Discharging?

Conductance testing measures your battery’s ability to conduct current, giving you a quick snapshot of its health. Because it doesn’t drain the battery, you get accurate results without risking any discharge. This method is a convenient way to check your battery’s condition safely and efficiently.

Conductance Measurement Process

Conductance measurement allows you to assess a battery’s condition without discharging it by sending a small, high-frequency signal through the plates. This process measures the internal impedance, which reflects the battery’s health. The conductance tester analyzes how easily this signal passes, providing insight into the electrical resistance within the cells. A low internal impedance indicates a healthy battery with good capacity, while higher impedance suggests aging or damage. Because no current is drawn from the battery during testing, it remains fully charged and ready for use. This method offers a quick, non-invasive way to evaluate the battery’s overall condition, making it ideal for routine maintenance and early detection of potential issues before failure occurs. Additionally, conductance testing is especially useful for supporting maintenance of batteries, as it enables timely interventions to prevent unexpected failures.

Benefits of Non-Discharge Testing

Because it doesn’t draw current from the battery, conductance testing provides a quick and safe way to evaluate its condition without risking any discharge or capacity loss. This benefits your battery’s lifespan and simplifies maintenance routines. Since there’s no need to fully charge or discharge the battery, conductance tests reduce wear and tear, helping you catch issues early. It’s ideal for regular checks, saving time and preventing unexpected failures. The table below highlights key advantages:

| Benefit | Explanation | Result |

|---|---|---|

| Preserves battery health | No discharging needed | Longer lifespan |

| Fast assessment | Immediate results | Efficient maintenance |

| No capacity loss | Safe testing method | Accurate condition monitoring |

| Suitable for routine checks | Easy integration into maintenance routines | Reduced downtime |

Conductance testing keeps your batteries performing at their best with minimal risk and minimal disruption to your device’s operation, which is especially important given the intricate craftsmanship involved in high-quality batteries, making it a preferred method among professional technicians. Additionally, the non-invasive nature of conductance testing makes it a valuable tool for preventive maintenance, reducing the likelihood of unexpected failures and extending battery life. Research indicates that sound waves can influence brainwave patterns, highlighting the importance of sound vibrations in health and wellness practices.

Main Differences Between Load Testing and Conductance Testing

While both load testing and conductance testing are essential methods for evaluating battery health, they differ considerably in how they assess a battery’s condition. Load testing measures actual battery capacity by applying a load and observing voltage drops, providing a direct view of how the battery performs under real-world conditions. It offers high testing accuracy but can be time-consuming and slightly intrusive. Conductance testing, on the other hand, estimates the battery’s health by measuring its ability to conduct electrical signals, which correlates with internal resistance. It’s faster, non-disruptive, and ideal for quick screenings. Additionally, conductance testing can be useful for ongoing battery monitoring without impairing the battery’s operation. Understanding the internal resistance and how it impacts overall battery performance helps in selecting the appropriate testing method. However, it may be less precise in determining true capacity, especially if the battery is nearing failure. Vetted methods like wave and wind testing can also be useful for specific applications.

When Should You Use Load Testing Versus Conductance Testing?

You should consider load testing when you need a clear view of your battery’s true capacity, especially if the condition indicators are unclear. Conductance testing, on the other hand, offers faster results and is less complex, making it ideal for quick assessments. Knowing when to choose each method helps you get accurate information efficiently.

Battery Condition Indicators

Determining the right time to use load testing versus conductance testing for battery condition indicators depends on the specific situation and the information you need. If you’re evaluating the battery’s current state of charge or predicting its longevity, conductance testing offers quick, non-invasive insights. It’s ideal for routine checks and identifying batteries that might soon fail. Conversely, load testing provides a more thorough evaluation by simulating actual usage conditions, revealing how the battery performs under stress. Use load testing when you need a definitive measure of capacity or suspect diminishing battery health. Both methods serve different purposes, so selecting the appropriate test depends on whether you’re seeking rapid condition indicators or a detailed performance assessment.

Testing Complexity and Speed

Choosing between load testing and conductance testing depends largely on how quickly and thoroughly you need to assess a battery’s condition. Load testing is more complex and takes longer but provides a detailed view of how the battery handles actual charge cycles and under real-world stress. Conductance testing is faster, ideal for quick checks, but may overlook issues caused by temperature effects or subtle charge cycle deterioration. Use conductance tests when you need rapid results, especially in routine maintenance. Opt for load testing when you suspect underlying problems or need a thorough diagnosis, despite the extra time. Here’s a comparison:

| Aspect | Load Testing | Conductance Testing |

|---|---|---|

| Speed | Slower | Faster |

| Complexity | More complex | Simpler |

| Accuracy in real-world | High, considers charge cycles | Moderate, affected by temperature effects |

| Best for | In-depth diagnosis | Quick screenings |

Pros and Cons of Load Testing for Battery Assessment

Load testing is a common method for evaluating a battery’s health because it simulates real-world conditions by applying a controlled electrical load. This approach helps you assess the battery’s ability to deliver power under typical usage, providing insights into its actual performance. One advantage is that it gives a clear picture of the battery’s remaining lifespan, allowing you to make informed decisions about replacement or maintenance. However, load testing can sometimes reduce the battery’s lifespan if done improperly or excessively. Additionally, testing accuracy depends on proper procedure; inaccurate testing can lead to misjudging the battery’s condition. While effective, load testing’s invasive nature and potential impact on longevity mean you should weigh its benefits against possible drawbacks for your specific needs.

Conductance Testing: Benefits and Drawbacks

Conductance testing offers a quick and non-invasive way to assess a battery’s health by measuring its ability to conduct electrical current. This method provides rapid results and is easy to perform, making it ideal for routine checks. However, it has limitations. The testing accuracy can be affected by battery aging, which impacts the conductance readings. As batteries age, their internal chemistry changes, possibly leading to less reliable results.

| Pros | Cons |

|---|---|

| Fast results | Less accurate for aged batteries |

| Non-invasive | Sensitive to temperature variations |

| Easy to perform | Can’t detect internal shorts |

| Good for routine checks | Less detailed than load testing |

| Portable and simple | Not suitable for all battery types |

While conductance testing is convenient, consider its drawbacks in relation to your specific needs.

How to Choose the Right Battery Testing Method for Your Needs

Selecting the right battery testing method depends on your specific needs, the type of battery you’re working with, and the level of detail required. If you want a quick assessment of battery health, conductance testing offers fast results and minimal disruption, ideal for routine maintenance routines. However, if you need a thorough understanding of your battery’s battery lifespan and performance under load, load testing provides more accurate insights. Consider how often you’ll test the batteries and the criticality of precise data—this influences your choice. For frequent maintenance routines, conductance testing might suffice, but for more in-depth analysis, load testing is preferable. Ultimately, choosing the right method ensures reliable performance, extends battery life, and optimizes maintenance efforts.

Industries That Rely on Load and Conductance Battery Testing

Many industries rely heavily on both load and conductance battery testing to guarantee equipment reliability and safety. In renewable energy, accurate testing ensures solar and wind storage systems operate efficiently, preventing costly failures. Electric vehicle manufacturers depend on conductance testing for quick battery assessments, ensuring safety and performance. The aerospace sector uses load testing to verify battery endurance during critical missions. Utilities test grid storage batteries to maintain a stable power supply. These testing methods help you identify weak batteries, reduce downtime, and avoid dangerous failures. Whether you’re working with renewable energy setups or electric vehicles, understanding and applying load and conductance testing is essential to safeguard your investments and keep systems running smoothly.

Tips for Selecting the Best Battery Tester

Choosing the right battery tester is essential for ensuring accurate results and reliable system performance. To maximize battery lifespan and testing accuracy, consider your specific needs. If you require quick, on-the-spot results, a conductance tester offers fast assessments but may sacrifice some precision. For detailed analysis, load testers provide thorough insights into battery health and capacity. Pay attention to the device’s compatibility with your battery types and sizes. Look for testers with clear displays and easy-to-use controls to reduce errors. Budget is also a factor—invest in a reliable model that balances cost with durability. Ultimately, selecting a tester tailored to your application helps you prevent premature battery replacements, extend lifespan, and maintain ideal performance.

Frequently Asked Questions

Can Both Testing Methods Be Used on All Types of Batteries?

Not all testing methods work for every battery type. Load testing is suitable for lead-acid batteries but can be harsh on other chemistries, while conductance testing is more versatile and gentle, often providing better testing accuracy across different battery chemistries like AGM or gel. You should select the method based on the battery’s chemistry and the level of testing accuracy you need to guarantee reliable results.

How Long Does Each Testing Process Typically Take?

Imagine time as your silent judge—load testing usually takes around 10-15 minutes, offering a thorough assessment with high testing accuracy but demanding more equipment. Conductance testing, however, is quicker, often just 2-5 minutes, providing rapid results with simpler equipment requirements. Your choice depends on how much time you have and the level of detail needed, balancing speed against testing precision.

Are There Safety Concerns With Load Testing Batteries?

Yes, load testing batteries can pose safety concerns if proper precautions aren’t followed. You should always wear safety gear, like gloves and eye protection, to prevent injury from acid or sparks. Be aware of hazards like overheating or short circuits, which can cause damage or injury. Make certain the testing area is well-ventilated and follow manufacturer instructions carefully to minimize risks and maintain safety during the process.

How Often Should Batteries Be Tested Using These Methods?

You should test your batteries at least every 3 to 6 months to monitor their battery lifespan and guarantee reliable performance. Regular testing improves testing accuracy and helps catch issues early. For batteries in critical applications, consider more frequent checks. Consistent testing helps you maintain ideal battery health, prevent unexpected failures, and extend their lifespan, especially when using accurate methods like load testing or conductance testing.

Do Testing Results Vary Based on Battery Age or Condition?

Yes, testing results can vary based on battery age and condition. As batteries undergo degradation, their capacity and performance decline, which can impact testing accuracy. Older or worn batteries may show lower readings, indicating potential issues, while newer ones might appear fine despite underlying problems. Regular testing helps you track battery health over time, ensuring you catch degradation early and maintain reliable performance.

Conclusion

Think of your battery as a crucial heartbeat, pulsing with energy. Choosing the right testing method is like listening closely—load testing is a deep, full pulse, while conductance testing is a quick, steady breath. By understanding their differences, you can guarantee your battery’s health shines brightly, just like a lighthouse guiding your way. Trust your instincts, and let the right test be the beacon that keeps your power flowing smoothly.